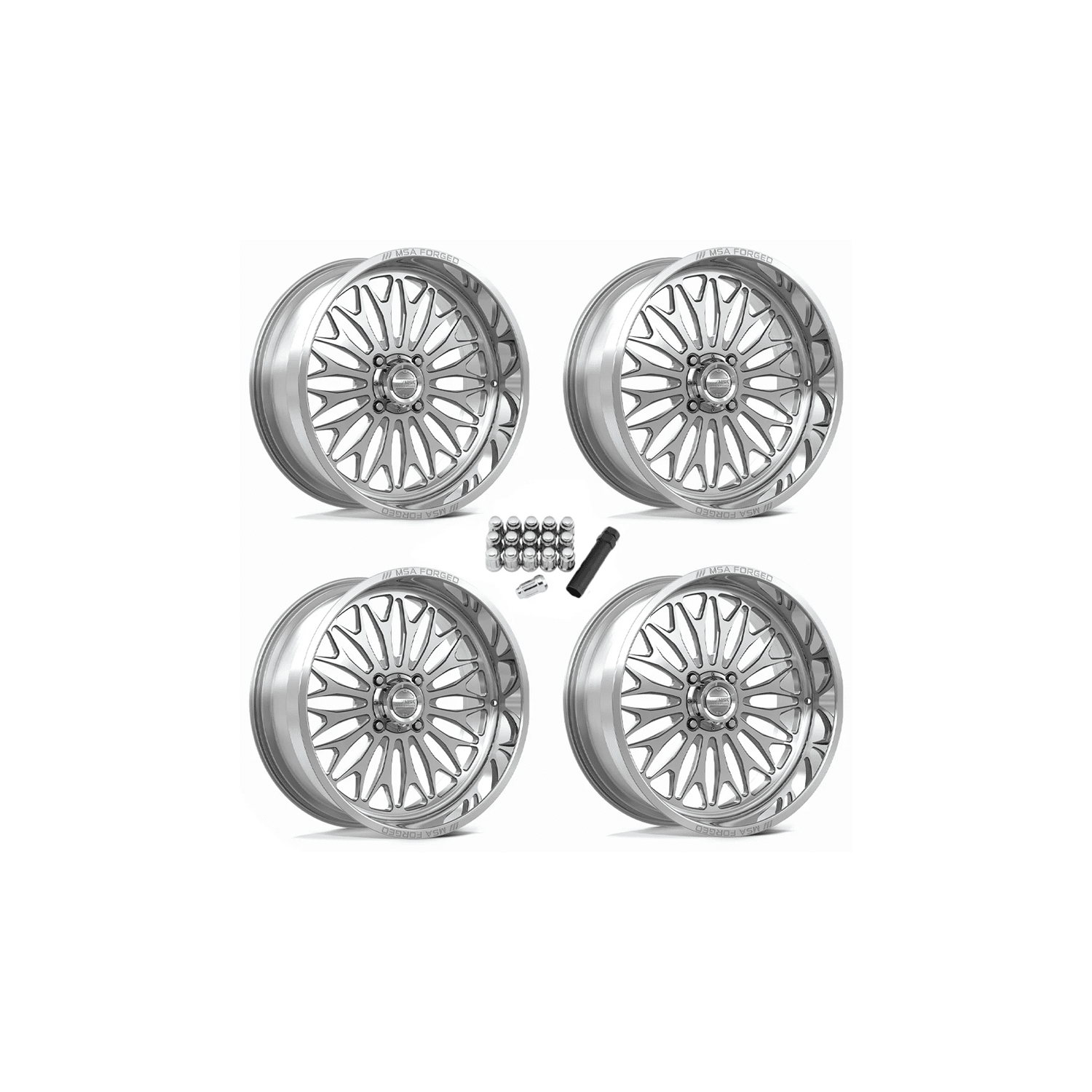

MSA Shockwave Forged Wheels: Strength, Style, and Performance

When upgrading your vehicle, the right wheels can transform both its look and performance. MSA Shockwave Forged Wheels offer unmatched strength and an aggressive design. Whether you’re an off-road enthusiast or simply want better performance, these wheels are a great choice.

What Are MSA Forged Wheels?

MSA Shockwave Forged Wheels are created using advanced forging technology. This process involves shaping high-quality aluminum under heat and pressure, making the wheels stronger than traditional cast wheels. As a result, these wheels are built to last and handle tough conditions, especially for off-road use.

Why Should You Choose MSA Forged Wheels?

Strength and Durability The forging process makes MSA Shockwave wheels much stronger than cast wheels. These wheels resist damage, even in harsh environments. Whether you’re off-roading or driving in the city, they’re built to last.

Lightweight and Improved Performance Despite their strength, these wheels are lightweight. This helps improve handling, acceleration, and braking. The reduction in unsprung weight gives your vehicle better control and a more responsive drive.

Bold, Aggressive Design MSA Shockwave Forged Wheels have a sleek, aggressive design. The bold look can instantly enhance your vehicle’s style. With sharp contours and a polished finish, these wheels make a statement wherever you go.

Off-Road Ready These wheels excel in off-road conditions. Whether you’re driving through rocky trails or muddy terrain, MSA Shockwave wheels perform reliably. Their rugged design ensures they can handle the toughest environments.

Low Maintenance Thanks to their durability, these wheels require less maintenance. They’re built to withstand harsh conditions, which means you spend less time on repairs and more time enjoying your ride.

The Technology Behind MSA Forged Wheels

MSA uses state-of-the-art technology to create these wheels. The process starts with a high-quality aluminum alloy, which is then heated and forged under high pressure. This makes the wheels denser, lighter, and stronger. Precision machining ensures a perfect fit for your vehicle. After production, each wheel undergoes strict testing to meet safety and performance standards.